WHY STEEL PLATES CREATE SPALLING

Ballistic fragmentation or spalling can occur during a ballistic event when armor steel is being impacted. These fragments that move beyond the steel plate could hit the operator or the team around the operator in the neck, head, or lower body. Thus resulting in secondary fragmentation injuries from the exploding bullet.

While steel is a popular option that stops many types of high-velocity projectiles and rounds, steel plates can create spall. Steel plates rely on their hardness to stop bullets which cause the impacting round to mushroom, fracture, and subsequently splatter upon impact.

Therefore, it is important to have additional fragmentation protection available to reduce/eliminate such fragmentation or spallation “spalling”.

To solve this problem, we encapsulate our steel plates with a tough elastomeric material called Rhino Extreme™ 11-50 Polyurea to reduce spalling.

ANTI-SPALL COATING

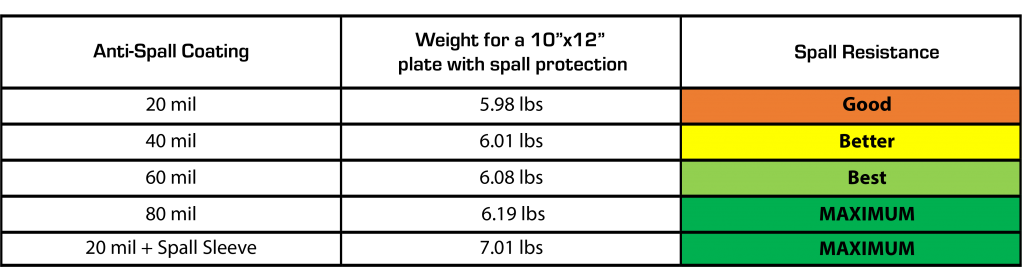

At HighCom Armor, we coat our steel plates (Guardian AR1000 / Guardian AR500) with military-grade Rhino Extreme™ 11-50 Anti-Spall Coating to dramatically reduce spall fragments from ballistic impact. We offer various levels of anti-spalling solutions to meet the needs of the end-user.

Operators can choose the thickness of the anti-spall liner ranging from 20 mil to 80 mil. Additionally, the plate can be inserted in our Guardian Rifle Insert Spall Sleeve for added frag protection.

SPALL TESTING

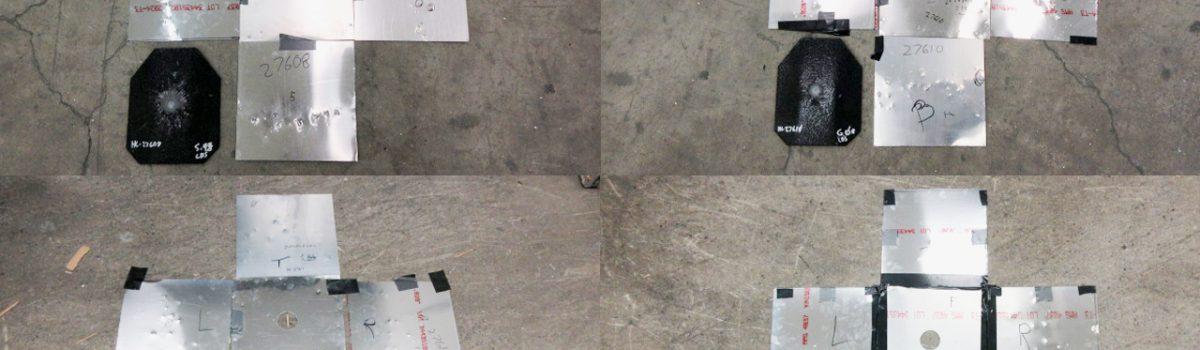

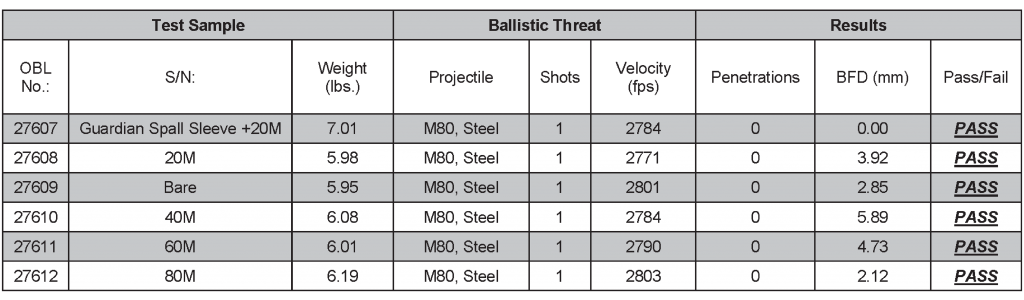

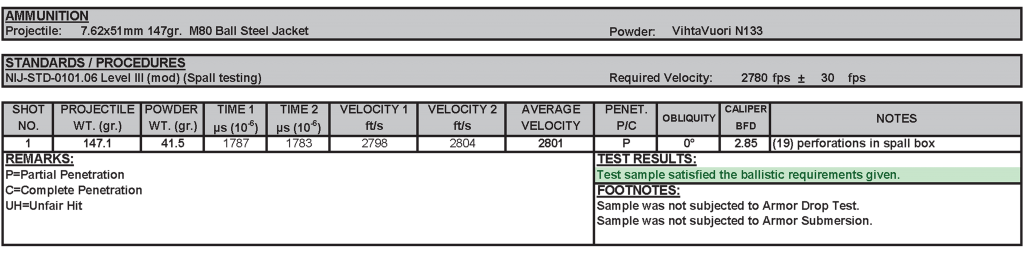

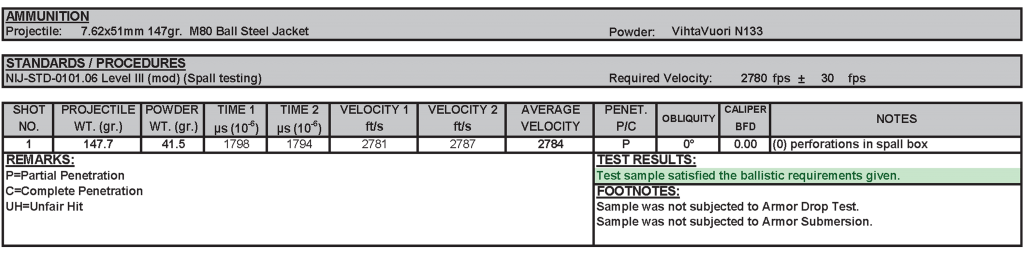

As part of our quality management, we regularly test our armor both in-house and independently. Below are spall test results of our Guardian AR1000 Level III+ Steel Plate with different levels of anti-spall coating.

All testing was performed by Oregon Ballistic Laboratories (OBL) an NVLAP Accredited Independent Laboratory.

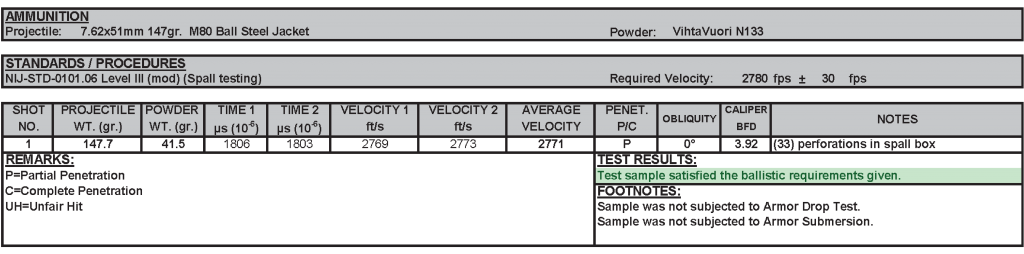

BARE STEEL

Spall test of the Guardian AR1000 Level III Steel Plate without anti-spall coating. This is bare steel being tested with M80.

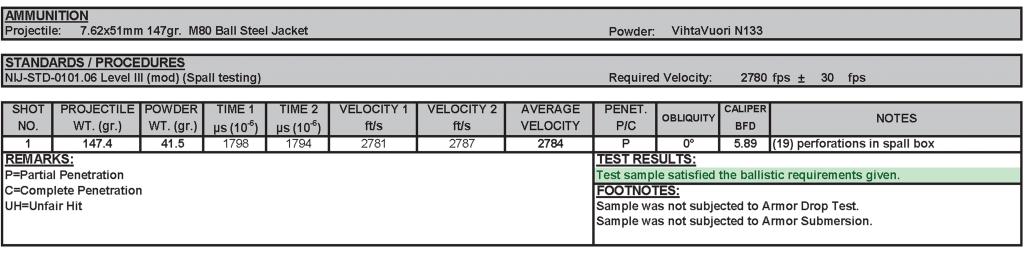

20 MIL RHINO COATED STEEL

Our 20 mil base offers GOOD anti-spall protection, robust weather, and chemical resistance. The base coat absorbs some fragmentation and helps to deflect any escaped frags away from the operator.

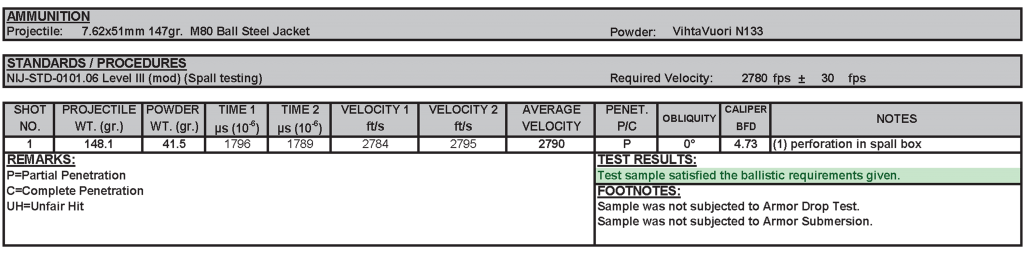

40 MIL RHINO COATED STEEL

Our 40 mil strike face coating offers BETTER anti-spalling protection while maintaining robust weather and chemical resistance, adding nominal weight, and adding better absorption.

This will absorb 40% more fragmentation than the base coating.

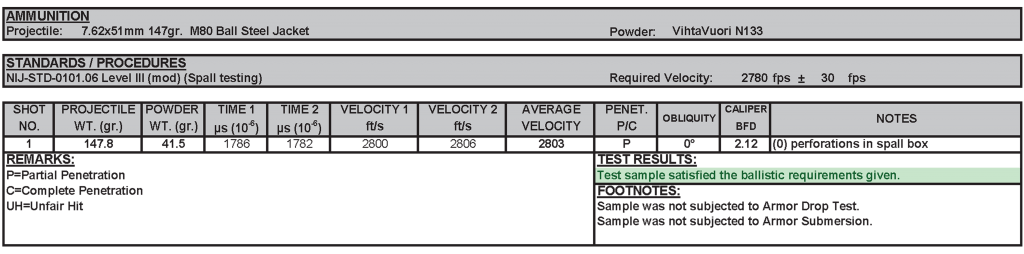

60 MIL RHINO COATED STEEL

Our 60 mil strike face coating offers the BEST anti-spalling protection while maintaining robust weather and chemical resistance, adding minimum weight, and offers the best absorption.

This will absorb 95% more of the fragmentation than the base coating.

80 MIL RHINO COATED STEEL

Our 80 mil Strike Face coating offers MAXIMUM anti-spalling protection while maintaining robust weather and chemical resistance, adding moderate weight, and offers maximum absorption.

This will absorb ~100% of the fragmentation.

20 MIL RHINO COATED STEEL + GUARDIAN™ SPALL SLEEVE

If you already have our standard Guardian Rifle AR500/AR1000 plate and would like total peace of mind for frag protection. HighCom is pleased to offer a Guardian™ Rifle Armor Insert Spall Sleeve option, that offers the MAXIMUM anti-spalling protection.

Thank you to our R&D and Engineering leadership team along with OBL our NVLAP Accredited Independent Laboratory for their assistance with this quality testing and article assembly. Request the completed test report with images and videos.

Want to learn more?