DO YOU KNOW THE VALUE OF YOUR RIFLE ARMOR WARRANTY?

We have all had experiences with products which didn’t live up to the hype. Computers, televisions, cars, washing machines, tools, all sorts of things. The first thing we do is go to the kitchen drawer stuffed full of manuals and warranties to find out whether or not we are still protected. Much of the time we find out that the product was already out of warranty.

Rifle armor, well that’s a different story. If rifle armor fails, catastrophe ensues.

SO WHY TALK ABOUT IT AT ALL?

Well, that’s simple. Our warranties are not just about getting you your money back. Our warranties are about making sure you never need your money back. Our NIJ 0101.06 compliant rifle armor is designed, manufactured and tested according to the highest industry standards. More importantly, our products are designed, manufactured and re-tested time and time again at and above published standards. HighCom is one of the only companies offering a full ten-year warranty on rifle armor. Nobody else is offering such a warranty because it is truly difficult to create and produce a product which a company feels confident enough in the processes and materials that they will continue protecting you beyond the industry five years. Our warranty is not designed to assure that you can get your money back ten years from now. It is designed to tell you that we trust our products so much that we can make such a promise. More importantly, the purpose of our warranty is to give our customers the confidence to know that using them, if – Heaven forbid – you should come under fire, you will go home.

In other industries, manufacturers talk about “Lifetime Warranties.” Our Ten-Year Warranties are REAL “Lifetime Warranties.” They are about the lifetimes of those wearing our NIJ compliant rifle armor. It is there to tell you that our users’ lifetimes matter to us above all else, that your family deserves the best real guarantee you can get.

GUARANTEED PERFORMANCE

Another important part for us is the DEA Hard Armor Protocol. DEA compliance is as important in defining the protection offered by our products as our warranties are. While the standards of the National Institutes of Justice are rigorous in their objective levels defining thickness and the ability to stop projectiles of various increasing calibers as well as non-projectile attacks, the DEA testing protocol takes this to another level with additional real-world threats and multi-hit testing in edge and close proximity to provide that additional layer of guarantee in performance of a product’s capabilities. This is one more step we take to ensure you will remain safe at the end of each and every shift. Objectivity is good. Concern for an operator and focus on saving lives above all else is better.

That is why HighCom adheres to both sets of standards; we don’t just meet those standards. Life is not graded on a “Pass-Fail” basis. We seek to excel and we never fail to do so. HighCom regularly exceeds industry standards and those of other law enforcement agencies such as the FBI.

At the same time, quality management systems guarantee the highest possible levels of excellence in both our processes and our products. We adhere to the NIJ’s BA9000 quality standards, which are re-evaluated every four years, requiring manufacturers to continually maintain their best performance. In fact, HighCom became the first company in the world to achieve BA 9000 certification, NIJ’s rifle armor quality management standard. By extension, BA9000 certified manufacturers need to be ISO 9001 compliant – and then some. To that end, HighCom has been ISO 9001:2008 certified since 2006. As with all outside standards to which we adhere, HighCom does not simply meet BA 9000 and ISO 9001 compliance, we go the extra mile to exceed those standards in every way we can. Our own ambitions for quality go above and beyond those demanded of us by certifying bodies.

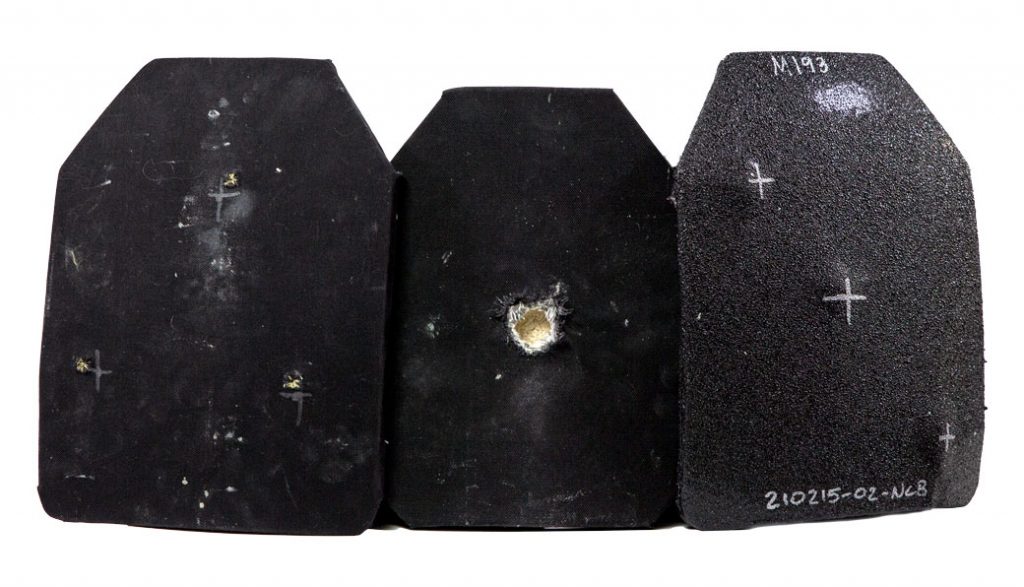

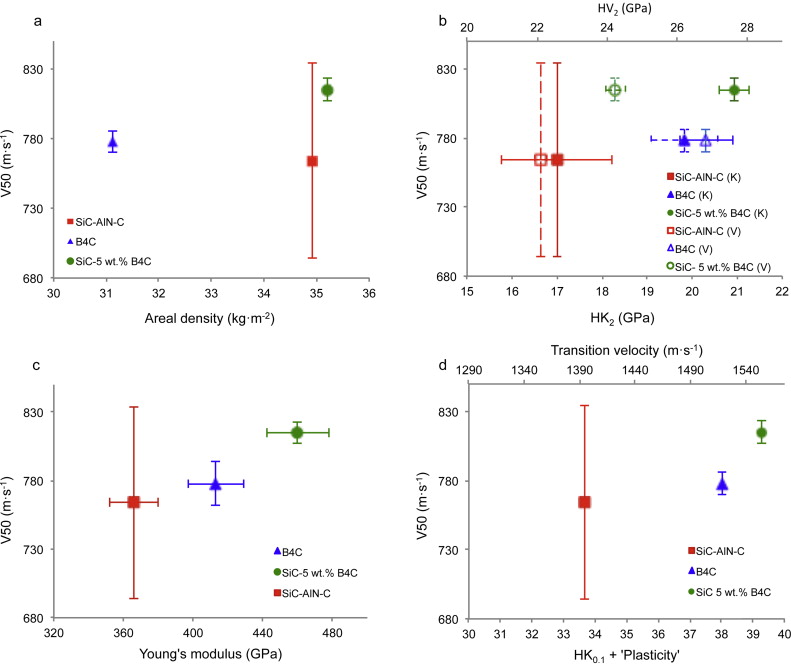

To ensure that our products do exceed industry standards, our R&D Division is constantly exploring and deploying technologically advanced innovative materials and approaches for offering greater protection to our users. To be certain that the solutions we choose to implement endow our products with the best possible protective characteristics, our in-house ballistic lab is continuously testing our armor against a wide variety of threats. We can – and do – test our armor against a wide range of rounds, from .22 caliber up to .50 caliber. Each and every product is proven 100% effective for the threats against which it is rated. We test all of our products, including our soft rifle armor, helmets, shields, rifle armor inserts and tactical armor systems.

Our customers include some of the best-known military, law enforcement and security organizations in the Global Community. These are agencies and enterprises which face danger on a daily basis. Their concern for the safety of their personnel is second to none. They entrust the lives of their people to HighCom. These are organizations who are far less concerned with a refund in the case of failure than they are with making sure there are no failures. Our unparalleled Ten-Year Warranty is an irrefutable sign that we know just how good our products are; and that we are more than ready to put our money and reputation on the line to demonstrate our full confidence behind each and every one of them.

Earlier this year, HighCom celebrated two decades of supplying top quality personal protective equipment to customers all over the world. The fact that a company with a 10-year warranty has achieved the milestone of 20 years in business truly says something. Our products are just that dependable. Your life is just that safe.